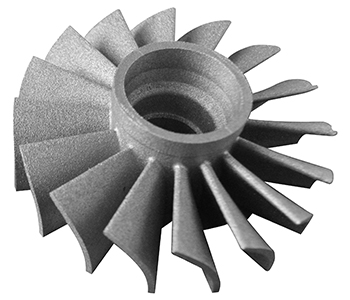

Metal Powder Bed Fusion Technology

Metal Powder Bed Fusion technology, which is also known as Selective Laser Melting.

Using the fiber laser can directly melt alloy metal powder layer by layer to produce high performance metal parts directly.

The build part forms layer after layer out of alloy metal powder, and the material utilization rate is pretty high by comparing with milling process, which is especially made for the manufacturing of metal parts, including titanium alloy, nickel alloy and other precious or difficult-processed metal material.

Wide Application

EP-M250 has wide application in aerospace, automotive, biomedical and tooling etc.

SPECIFICATIONS

Build Volume (X*Y*Z): 262x262x350mm³

Spot Size: 70μm

Max Scan Speed: 8m/s

Layer Thickness: 20-100μm

Build Speed: 5-20cm³/h *

Material: Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc.

Power: 380V, 26A, 50/60Hz, 10KW

Gas Supply: Ar/N₂

Oxygen Content of Chamber: ≤100ppm

Dimensions (W*D*H): 2500x1000x2100mm³

Machine Weight: 1500kg

Control Software: Eplus 3D printing software

Input Data Format: STL or other convertible file

Laser: Fiber laser, 200W/500W (optional)