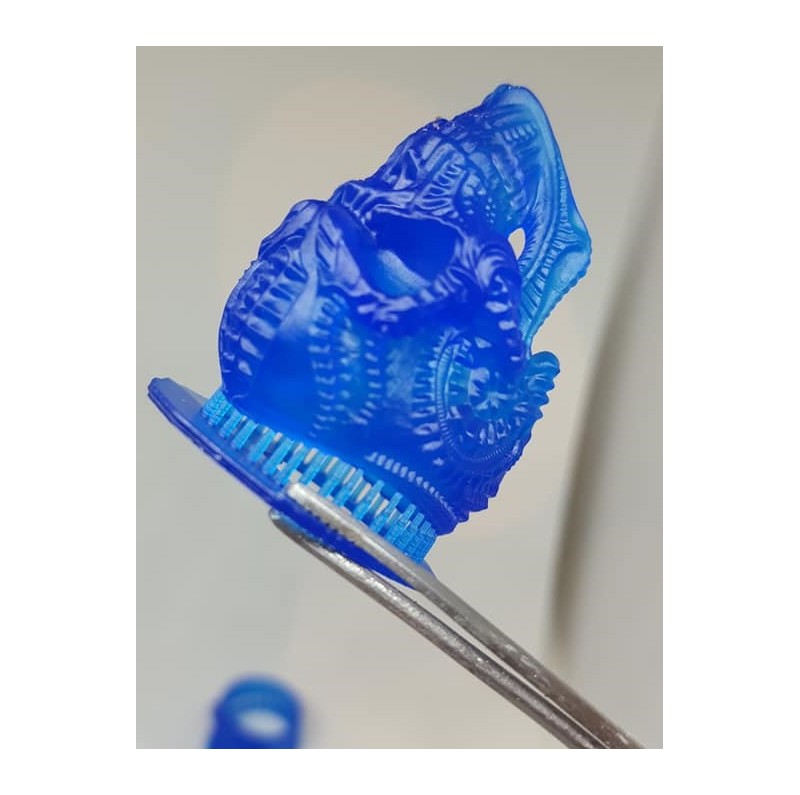

Tuned for Formlabs 3d printers and compatible with other SLA machines (405 nm).

Minimal residue after burnout process (0.003%)

Low-exhaust emission during the burnout process

Virtually no expansion of resin during burnout process

Extreme castability

Ultra-fast burnout cycle available (1 hour)

Compatible with all investments (Tested with Kerr® Satincast, R&R PlastiCast, Optima Prestige, Omega Plus)

No UV post-curing necessary

Washable with 90%/99% denatured alcohol (IPA) or ethyl alcohol 90%/99%

Less irritation, free of toxic substances

Low deformation post-printing

Direct casting of models with no need for lacquer or Teflon® (PTFE) spray

Exceptional hand workability (UV post-curing needed to harden big models)

Suitables for classic jewelry and silver design